The purpose of the transmission is to direct the energy generated by the engine to the PTO or drive shafts. Since the internal combustion engine of a conventional vehicle is powerless, gears or gear changes must be used to increase the force. The theory is simple – you have to choose the right gear to move the vehicle and turn on the next gear at the right moment.

Before the introduction of electronics, the automatic transmission operated as a hydraulic computer. The vehicle’s speed-dependent oil pressure attempted to turn off the gears (the higher the speed, the higher the gear) and the throttle-dependent pressure attempted to turn off the gear (the more you push the pedal, the more the driver wants to accelerate, so we lower the gear). Their “struggle” gave rise to a decision when to switch gears and either to swap up or down.

The hydraulic circuit is very complicated on such transmission, but also very reliable. True, gear shifting speed and comfort were not comparable to modern transmissions.

Nowadays, when electronic control units are used, the situation is actually the same – the control unit determines, on the basis of information from various sensors, when and how the gear is switched on or off.

The old hydromechanical transmission took into account only the vehicle speed, engine load and throttle position. The new transmission also take into account the driver’s driving style, environmental requirements, temperature, oil and gear aging and wear, and even whether the car is driving in the curves or not.

Types of transmissions

As stated, the term “transmission” is generally understood to mean a mechanical assembly that directs the mechanical energy of the engine through the wheels of the drive shafts. The transmission receives the input through the clutch motor and, depending on the gear selection, repeats or reduces the force.

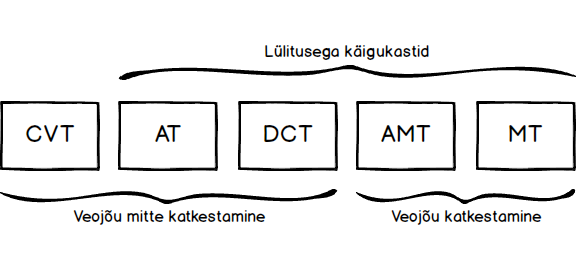

All transmission have one common line – different transmission speed depending on the need and the possibility to change the direction of transport (reverse gear). Transmission are in fact very different types and it is more common to distinguish between them according to whether the traction is interrupted or not at the moment of changing the gear.

The cut-off of the tractive effort is happens when the engine is disconnected from the transmission at the moment of switching the gear – for example, by means of a manual transmission (MT) on the vehicle when the clutch is pressed.

Similarly, this is also the case with AMT (Automated Manual Transmission), where the so-called robot is switched on and clutched by the manual transmission. In both cases, the disadvantage is that the gear switching is long and that it is felt.

CVT, AT and DCT are all transmissions that do not reduce the traction power when changing gears (changing transmission) but the acceleration is steady and smooth. In our work, we actually focus on these three types of transmissions:

- planetary transmission (AT – Automatic Transmission);

- continuously variable transmission (CVT);

- double-clutch transmission (DCT i.e. DSG).

All of the above-mentioned variants can be connected to a greater or lesser extent to hybrid propulsions, making the transmission partially or completely electric.